Low cost - High Quality Sensorex conductivity probes are suitable for use with most portable conductivity meters. Add a simple mounting gland fitting, and you can use these in process applications. Mount them in-line, in a pipe "T" fitting, or submerse them into a tank.

The general purpose CS150 features graphite measuring elements and a durable epoxy body. For many applications, this is the lowest cost, and most reliable conductivity sensor to use, especially for process or portable applications.

Specifications

| Cell Constant: |

k=0.1 or k=1.0 (+/- 10%) |

| Measuring Surface: |

Graphite |

| Temperature Range: |

0-70°C |

| Pressure Range: |

0-7.5 Bar |

| Body Construction: |

Epoxy |

| Termination: |

BNC, Cable with flying leads |

| Warranty: |

1 Year Limited Warranty |

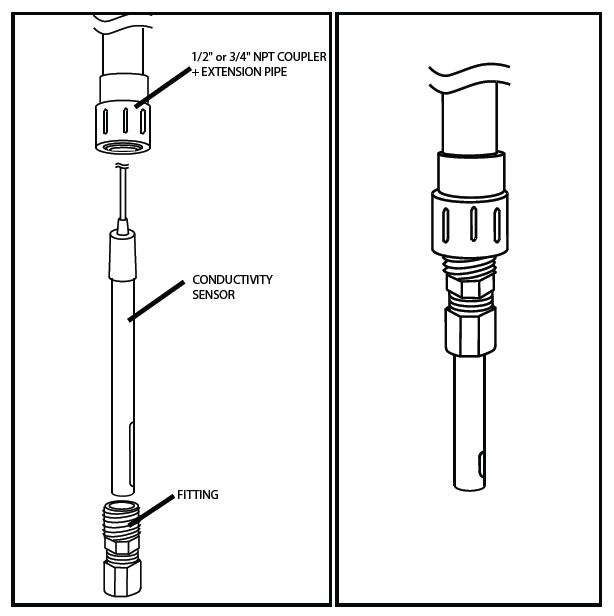

Submerged Installation

The CS150 electrode can be submerged and mounted in a tank to take conductivity measurement using gland and ½” NPT or ¾” NPT fitting. The fittings must be installed in an inverted position so the nut is pointed downwards. Loosen the nut by turning clockwise (remember that fitting is inverted). Slip electrode through hole in nut until desired depth is reached. Tighten nut (hand-tight) by turning counterclockwise.

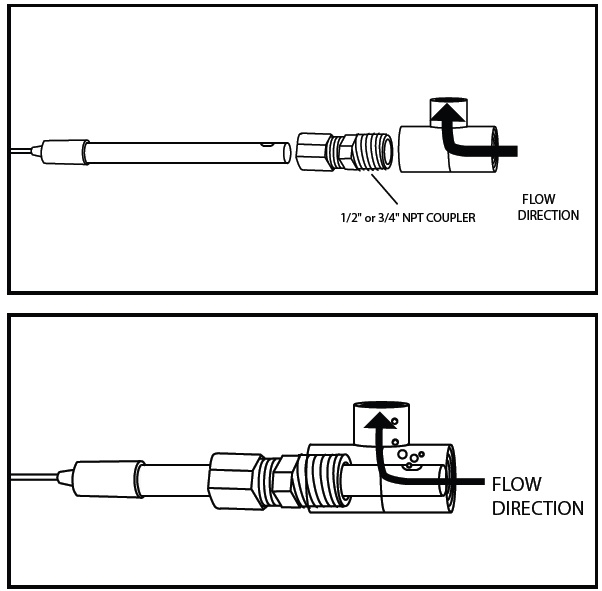

Inline Installation

The CS150 can be mounted in-line using the ½” NPT or ¾” NPT fitting. It is recommended that sensors are mounted through the side of a tee piece as shown on the diagram. The sensor should be mounted such that the opening/slot in the body is pointed upwards. This ensures any air bubbles rise out of the sensor and escape with the flow.

In both installation methods, Teflon tape should be used to ensure a seal on the threaded connections.

Care and Cleaning

CS150 electrodes have a Graphite measuring surface. The surfaces should be cleaned using a gentle detergent or 5% HCl in a suitable cup or beaker. Do not sand or abrade the Graphite surface as abrasion changes the surface area and will cause erroneous readings.