omni instruments | sensors and data acquisition equipment

Edit Content

The DBB series of loadcells are an S beam, bi-directional load cell suitable for tension and compression applications. Loadcells are available with a bi-directional range of 50Kgf up to 10,000Kgf with a standard 2mV/V output and accuracy of 0.03%. The smaller DBBE is an encapsulated cell sealed to IP67. Units can be supplied with suitable inline amplifiers to provide a calibrated 4-20mA output

The DBB series ‘S-beam load cell’ is designed for force measurement and weighing applications alike and can be used for tension and compression measurements. It’s ease of mounting makes it very attractive for use as a general purpose load cell.

There are two versions available within the standard range. The smaller DBBE is an encapsulated cell sealed to IP67 (covering ranges of 50kgf up to 1,000kgf), the DBBWAS covers ranges above 1000Kgf.

| DBBE | DBBWAS | |

| Standard Capacities (Kg): | 0-50, 0-100, 0-150, 0-200, 0-300, 0-500, 0-1000 | 0-1500, 0-2000, 0-3000, 0-5000, 0-6000 |

| Sensitivity: | 2.0mv/V ±0.1% | |

| Zero Balance/Offset: | <±2.0% Rated Output | |

| Total Error: | <±0.03% Rated Output | |

| Zero Return after 30 mins: | <±0.03% Applied Load | |

| Input Resistance: | 400 ±20 Ohms | |

| Output Resistance: | 350 ±3 Ohms | |

| Insulation Resistance: | >2000 Megaohms @ 50vDC | |

| Excitation Voltage: | 10vDC Recommended (2-15vDC Acceptable) | |

| Operating Temperature: | -30 to +70°C | |

| Compensated Temperature: | -10 to +45°C | |

| Storage Temperature: | -30 to +70°C | |

| Safe Overload: | 150% of Rated Capacity | |

| Ultimate Overload: | 300% of Rated Capacity | |

| IP Rating: | Standard IP67 | |

| Fatigue Life: | 108 Cycles Typical (109 cycles on fatigue-rated version) | |

| Cable: | 6m, 6-Core Screened, PUR Sheath | |

| Construction: | Nickel Plated Alloy Steel | |

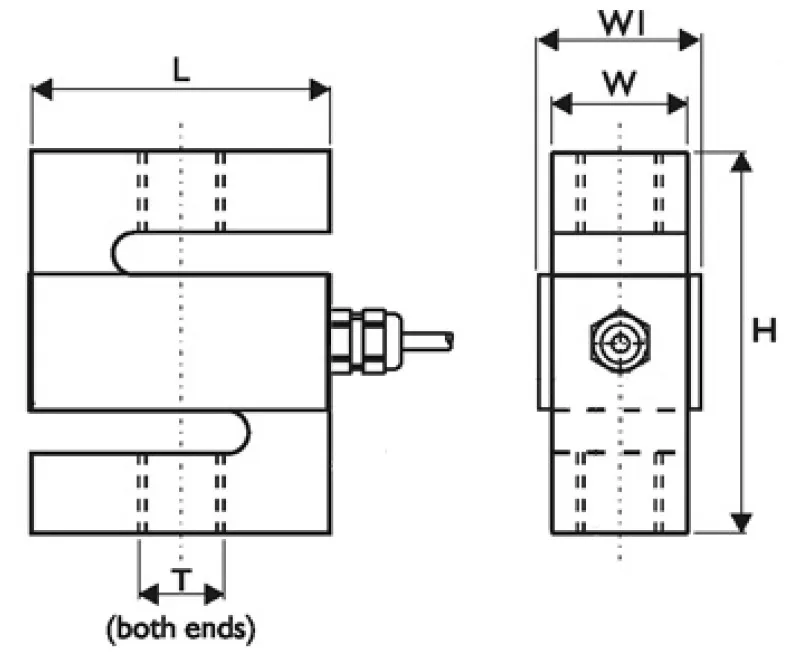

| Model | Capacity | H | L | ¶W | W1 | ¶H1 | Threads T |

| DBBE | 0-50 up to 0-1,000Kgf | 80 | 62.1 | 18 | 22 | 15 | M12 x 1.75 |

| DBBWAS | 0-1,500Kgf | 90 | 70 | 32 | 36 | 19 | M16 x 2.0 |

| DBBWAS | 0-2,000Kgf | 90 | 70 | 32 | 36 | 19 | M16 x 2.0 |

| DBBWAS | 0-3,000Kgf | 120 | 100 | 45 | 45 | 26 | M24 x 2.0 |

| DBBWAS | 0-5,000Kgf | 120 | 100 | 45 | 45 | 26 | M24 x 2.0 |

| DBBWAS | 0-6000Kgf | 120 | 100 | 45 | 45 | 26 | M24 x 2.0 |

The optional load buttons and rod end bearings are designed to align forces through the principle axis of the load cell, reducing the effects of extraneous forces. Load Buttons are used for compressive forces and Rod End Bearings are used for tensile forces.

RODENDM12X1.75

£41.00

RODENDM16X2.0

£52.00

RODENDM24X2.0

£90.00

LOADBUTM12X1.75

£79.00

LOADBUTM16X2.0

£79.00

Need help with your products or have a question for us on our custom systems? Use the form below to send us a message and our experts will be in touch to help.