Downloads

SGR520 Digital Torque Transducer

Description

Key Benefits

- Any full scale torque can be specified within the standard range: 1Nm through to 13,000Nm

- Large fully functional overrange capabilities of 250%

- Minimal side and end load errors

- Low Linearity deviation of ±0.05% FSD

- Low Hysteresis error of ±0.05% FSD

- Zero vaiation in torque signal with rotation (Cyclic Variation)

- Non contect signal transmission, no slip rings to wear out.

- High digital sample rate of 4,000 samples per second

- Adjustable torque data smoothness, low pass filter

- Wide Power Supply range 12-32vDC

- Lifetime Warranty

The TorqSense SGR520 transducers offers, these additional features:

- 2 x user selectable voltage or current analog outputs (one for torque and the other for speed, power or peak torque)

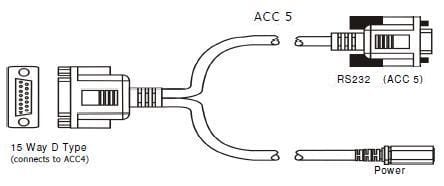

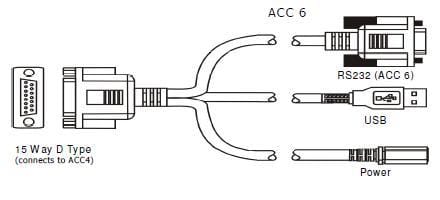

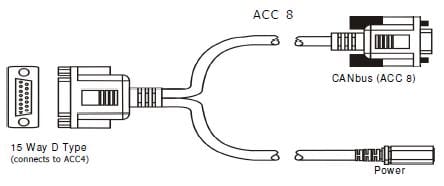

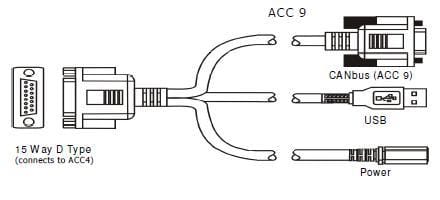

- Digital outputs such as RS232, CANbus and USB for interfacing with modern instrumentation and laptops

- Digital input for configuring transducer via PC

- BIT Self-diagnostics for letting users know data is trustworthy, that the transducer torque or speed ratings have not been exceeded and the transducer’s calibration date

- Transducer configuration software to allow user to changes transducer variables

- Sensors to monitor shaft temperature for better compensation and accuracy

- Simple ‘Sensor Status’ output pin

- Ability to connect up to 10 transducers using USB

Operating Principles

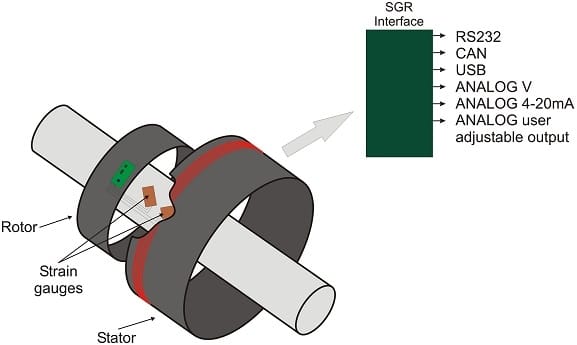

The SGR series transducers operate using a four-element strain gauge wheatstone bridge, which is connected to a miniature shaft mounted analog to digital converter and microcontroller. The microcontroller conditions and measures the strain gauge bridge output as close to the gauges as possible, eliminating any possible external noise pick up in the gauge wiring.

The shaft mounted electronic module is wirelessly powered by a radio frequency source which drives a stator coil, the output of which is received by a rotor coil on the shaft thus making the system completely contactless. This eliminates the need for slip rings and their associated wear and noise problems.

The shaft microcontroller outputs a digital serial stream that is transferred back from rotor to stator by modulating the impedance of the rotor coil and detecting the impedance changes at the stator coil. A secondary high-performance microcontroller receives the serial stream from the shaft microcontroller, which then performs calibration and temperature compensation before outputting the results digitally via RS232, CAN bus or USB. A 16-bit digital to analog converter also outputs the sensors data as a fully calibrated and compensated analog voltage or current.

Torque ranges available at any full scale torque: 1Nm to 13,000Nm, with above 13,000Nm on request.

First Annual Recalibration is included in the purchase price. Units must be returned to Omni Instruments for Recalibration.