Downloads

PR 4131 Universal Trip Amplifier

Description

Applications

- Process control with 2 pairs of potential-free relay contacts which can be configured to suit any application.

- Trip amplifier with window function defined by a high and a low setpoint. The relay changes state outside the window.

- Relay latch function, where the relay is activated and can only be reset manually.

- Sophisticated sensor error surveillance, where one relay holds the state immediately prior to the sensor error, thus allowing the process to continue. The other relay can be set for sensor error alarm so that the defect sensor can be replaced immediately.

Features

- Input for RTD, TC, Ohm, potentiometer, mA and V

- 2 adjustable alarm limits

- FM-approved for installation in Div. 2

- 2 relay outputs

- Universal AC or DC supply

- Programmable via detachable display front (4501), process calibration, relay simulation, password protection, error diagnostics and selection of help text in several languages.

4510 Display/Programming Interface

Application:

- Communications interface for modification of operational parameters in 4131.

- Can be moved from one 4131 module to another and download the configuration of the first converter to subsequent converters.

- Fixed display for readout of process data and status

Technical characteristics:

- LCD display with 4 lines; line 1 (H = 5.57 mm) shows input signal, line 2 (H = 3.33 mm) shows units. Line 3 alternates between digital output value and scaling (kHz, Hz, mHz, P/m, P/h, P/d) or shows TAG no. Line 4 shows tendency readout for the input signal and communication status.

- Programming access can be blocked by assigning a password. The password is saved in the converter in order to ensure a high degree of protection against unauthorised modifications to the configuration.

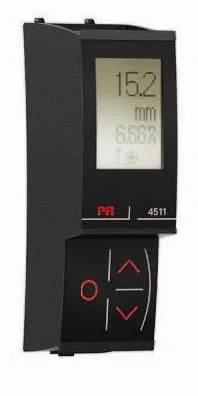

4511 Modbus Communications Interface

Application:

- The 4511 detachable display adds Modbus RTU RS485 serial communications to all current and future 4000/9000 series units

- All individual unit operating parameters can easily and quickly be configured by using the Modbus communication or by using the front display menu

- The 4511 display can be used to read the process signal, simulate the output signal, indicate sensor errors and internal device errors

Technical characteristics:

- 4511 has full 4501 functionality for programming and display

- RS485 Modbus RTU protocol

- Multi-drop half-duplex connection via shielded RJ45 connector on top of module

- Modbus parameters such as address, baud rate, stop bit(s) and parity bits are configured from, and stored on, the 4511 interface

- 2.5kVAC galvanic isolation between serial wiring and 4000/9000 units

4512 Bluetooth Communications Interface

Application:

- Program devices via Bluetooth using an iOS/Android device running the free PPS app (PR Process Supervisor).

- Use PPS data for preventive maintenance.

- All logged data can be exported in .csv format, for advanced data analysis off-site.

- On-site analysis of real-time process data on an iOS/Android compatible device.

- Off-site analysis of historic process data on a PC using PReset.

Technical characteristics:

- PR 4512 runs Bluetooth 4.2, and requires a smart device with 4.0 or newer.

- PPS is compatible with iOS and Android devices.

- The PR 4512 automatically detects the device setting on the connected PR 4000 and 9000 device.

- An internal battery energizes the 4512 real-time clock for at least 2 years, should the 4512 remain de-energized.

- Typical data logging capacity is more than 30 days at 1 second intervals.

- Easy to read dot matrix LCD display.

- Fast pairing or safe pairing via two-factor authentication.

Android App for 4512 Interface

Android App for 4512 Interface

The image on the right links to the Google Play store to download the PR Electronics PPS application used to enables Android devices to connect to the Bluetooth Communications Interface. The app allows for the configuration, viewing of sensor live data and collection of logged data using the wireless Bluetooth connection.

If required, Omni Instruments will program a 4131, 4501, 4511, or 4512 to your specific requirements. Please contact us for details.