Downloads

MicroCal Simulators

Description

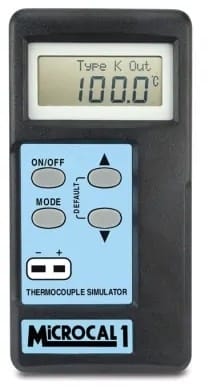

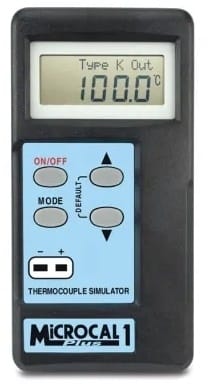

The MicroCal Thermocouple Simulator is a valuable tool for ensuring the accuracy, reliability, and safety of temperature measurement systems in various industries. The MicroCal 1 can simulate thermocouple signals for multiple different thermocouple types in a single instrument. The MicroCal 1+ does the same as the MicroCal 1 but can also measure, allowing it to test the sensor and simulate the correct output to test equipment.

Both MicroCal 1 models feature a custom 10mm LCD display with alpha-numeric display line to prompt the user when changing parameters. Selectable parameters include: °C/°F, auto power off – enable/disable, CJC – internal/external and display contrast adjustment.

Each MicroCal is supplied with a one metre PVC type K thermocouple lead with miniature connectors and a five point UKAS Certificate of Calibration which will indicate deviations from standards at the various points.

Specifications

Ranges:

| K-Type Thermocouple: | -200 to +1372°C |

| J-Type Thermocouple: | -200 to +1200°C |

| T-Type Thermocouple: | -270 to +400°C |

| R-Type Thermocouple: | 0 to +1768°C |

| N-Type Thermocouple: | -200 to +1300°C |

| S-Type Thermocouple: | 0 to +1768°C |

| E-Type Thermocouple: | -140 to +1000°C |

| Accuracy: | ±0.3°C |

| Battery: | 2 x 1.5 Volt AAA |

| Battery Life: | 300 Hours |

| Display: | Custom LCD |

| Dimensions: | 35 x 73 x 141 mm |

| Weight: | 220 grams |

Accessories

The protective PVC boot helps to protect instruments against accidental damage. An optional lead set is also available, that comprises of seven leads, one for each thermocouple type K, J, T, R, N, S and E. Each PVC lead is one metre long and incorporates two miniature thermocouple plugs. Both accessories are suitable for all types of the MicroCal simulators/thermometers.

The MicroCal 1 Thermocouple Simulators can be used for the following purposes:

Calibration of Thermocouples and Instrumentation:

- Accuracy Verification: The MicroCal 1, or MicroCal 1+ will generate the precise electrical signal to mimic the output of various types of thermocouples, at specific temperatures. By connecting the simulator to a thermocouple-based instrument, technicians can quickly verify the accuracy of the instrument’s readings.

- Troubleshooting: MicroCal simulators help identify issues with thermocouples or instrumentation. If the instrument doesn’t respond correctly to the simulated signals, it indicates a problem with the thermocouple, its wiring, or the instrument itself. The MicroCal 1+ can then measure the reading from the thermocouple to find if the error is with the thermocouple sensor, logger, or wiring between the two.

- Calibration of Temperature Transmitters: Many industrial processes use temperature transmitters to convert thermocouple signals into standard signals like 4-20mA. Simulators are essential for calibrating these transmitters to ensure accurate temperature readings. The MicroCal 1 can be used to generate precise readings of types K, J, T, R, N, S and E Thermocouples at 12 preset temperature values allowing all to be test with one instrument.

Testing and Maintenance:

- System Verification: MicroCal 1+ Simulators can be used to test the entire temperature measurement system, including thermocouples, wiring, transmitters, and control systems, to ensure they are functioning correctly.

- Predictive Maintenance: By regularly testing with the MicroCal 1, or MicroCal 1+, simulators, potential problems can be identified before they lead to costly downtime or inaccurate measurements.

Training and Education:

- Hands-on Training: Simulators provide a safe and controlled environment for technicians to learn about thermocouple behaviour, calibration procedures, and troubleshooting techniques.

- Students: Can utilise the MicroCal simulators to see how monitoring equipment respond, without the need to generate high temperatures.

Benefits of Using Thermocouple Simulators:

- Improved Accuracy: Regular calibration with simulators ensures accurate temperature measurements, which is critical in many industries.

- Reduced Downtime: By identifying and addressing problems proactively, simulators help minimize costly equipment downtime.

- Enhanced Safety: Accurate temperature measurements are essential for safety in many applications, such as in industrial processes and research environments.

- Cost-Effectiveness: Simulators can help reduce the overall cost of ownership by preventing costly equipment failures and ensuring compliance with industry standards.