Downloads

DSCC Load Cell

Description

The DSCC series are low profile pancake type load cells suitable for both Weighing and Force Measurement applications. Constructed from Stainless Steel, offering excellent corrosion resistance and improved zero force pass through performance over conventional steel products. The load cell’s design provides excellent resistance to extraneous forces, such as bending, side and torsional forces.

The load cell is used widely in material and fatigue testing applications, where a low physical height is required and forces are applied axially. The mounting bolts for all capacities are counterboard to prevent obstruction from the bolt heads. High frequency response is also a benefit with this load cell for dynamic force measurement applications, which is also complimented with excellent fatigue resistance.

Features

- Capacities: DSCC 5kN to 1000kN

- Stainless Steel Construction.

- Low Profile Shear Design

- Low Deflection

- High Natural Frequency

- Excellent Rejection of Extraneous Forces

- Optionally Fatigue Rated, fully reversed full range cycles.

- Shunt Calibration Facility

- 3-YEAR WARRANTY

Options

- Other ranges available on request

- Higher Accuracy Versions Available (consult factory)

- Equivalents to other manufacturers’ available

- Full range of mounting options available including: Load Buttons, Spherical Rod End Bearings, Standard and Special Mounting Base.Different Centre Thread Sizes (consult factory)

- Integral Cable Versions (consult factory)

- Double Bridge Versions

- TEDS Available for Plug & Play with TEDS Enabled Instrumentation, eg. TR150 Display

Applications

- Materials Testing

- Component Fatigue Testing Applications

- Dynamic Force Applications

- Calibration Test Rigs

- Crash Test Walls

- General Load & Force Measurement

- Press Force Monitoring & Verification

Specifications

| Standard Capacities (kN): | 0-5, 0-10, 0-25, 0-50, 0-100, 0-200, 0-250, 0-300, 0-500, 0-750, 0-1000 |

| Sensitivity: | 2mV/V Nominal (up to 200kN) / 2.7mV/V Nominal (250kN upwards) |

| Zero Balance/Offset: | <±1.0% Rated Output |

| Non-Linearity: | <±0.05% Rated Output |

| Hysteresis: | <±0.05% Rated Output |

| Repeatability: | <±0.05% Rated Output |

| Input Resistance: | 700 Ohms Nominal |

| Output Resistance: | 700 Ohms Nominal |

| Insulation Resistance: | >5000 Megaohms @ 50vDC |

| Excitation Voltage: | 10vDC Recommended (2-15vDC Acceptable) |

| Operating Temperature: | -20 to +80°C |

| Compensated Temperature: | 0 to +70°C |

| Storage Temperature: | -20 to +80°C |

| Safe Overload: | 150% of Rated Capacity |

| Ultimate Overload: | >250% of Rated Capacity |

| IP Rating: | IP65 |

| Fatigue Life:

|

Standard Versions: 30-50 million typical Fatigue-Rated Versions: 500 million Versions rated to 1 billion+ on request |

| Cable (Single Bridge): | 3m, 4-Core Screened, PUR Sheath via 6-pin Amphenol Connector |

| Cable (Dual Bridge): | 3m, 8-Core Screened, PUR Sheath via 8-pin M12 x 1.0 Connector |

| Construction: | Stainless Steel |

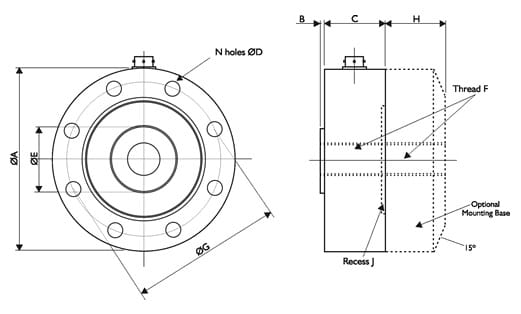

Dimensions

| Model | Capacity | ØA | B |

C |

ØD | ØE | Thread F | ØG | N holes | H |

J | Resonant Frequency (kHz) |

Extraneous Load Limit (Mx, My or mZ) (nM) |

| DSCC | 0-5kN | 107 | 2 | 33 | 8.5 | 33 | M20 x 2.5 | 90 | 8 | 35 | 2 | 3.5 | 30 |

| DSCC | 0-10kN | 107 | 2 | 33 | 8.5 | 33 | M20 x 2.5 | 90 | 8 | 35 | 2 | 4.5 | 60 |

| DSCC | 0-25kN | 107 | 2 | 33 | 8.5 | 33 | M20 x 2.5 | 90 | 8 | 35 | 2 | 6.5 | 150 |

| DSCC | 0-50kN | 107 | 2 | 33 | 8.5 | 33 | M20 x 2.5 | 90 | 8 | 35 | 2 | 7.2 | 300 |

| DSCC | 0-100kN | 155 | 3 | 45 | 11 | 60 | M36 x 2.0 | 130 | 12 | 45 | 2 | 6.5 | 845 |

| DSCC | 0-200kN | 155 | 3 | 45 | 11 | 60 | M36 x 2.0 | 130 | 12 | 45 | 2 | 7.8 | 1690 |

| DSCC | 0-250kN | 155 | 3 | 45 | 11 | 60 | M36 x 2.0 | 130 | 12 | 45 | 2 | 8.7 | 2000 |

| DSCC8 | 0-250kN | 202 | 2 | 52 | 12.2 | 95.5 | M56 x 4.0 | 165 | 16 | 50 | 2 | 9.0 | 1500 |

| DSCC8 | 0-300kN | 202 | 2 | 52 | 12.2 | 95.5 | M56 x 4.0 | 165 | 16 | 50 | 2 | 9.3 | 1800 |

| DSCC8 | 0-500kN | 202 | 2 | 52 | 12.2 | 95.5 | M56 x 4.0 | 165 | 16 | 50 | 2 | 10.0 | 3000 |

| DSCC | 0-300kN | 278 | 6 | 78 | 17 | 118 | M64 x 6.0* | 230 | 16 | 84 | 4 | 8.7 | 2030 |

| DSCC | 0-500kN | 278 | 6 | 78 | 17 | 118 | M64 x 6.0* | 230 | 16 | 84 | 4 | 8.9 | 3390 |

| DSCC | 0-750kN | 278 | 6 | 78 | 17 | 118 | M64 x 6.0* | 230 | 16 | 84 | 4 | 8.9 | 3390 |

| DSCC | 0-1000kN | 278 | 6 | 78 | 17 | 118 | M64 x 6.0* | 230 | 16 | 84 | 4 | 9.0 | 6780 |

*Rod End Bearings require M64 x 4.0 Thread, Max static load 689kN.