Description

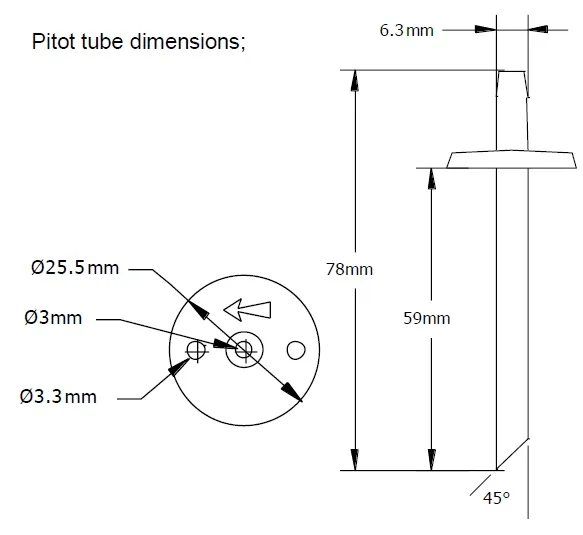

The DFK set features a characteristic 45° angled cut at the tips, specifically designed to capture the energy of moving air. When the probe facing the airflow (the impact probe) is installed, the angled opening “catches” the air, measuring the combination of static and dynamic pressure. Conversely, the probe angled away from the flow creates a slight suction effect. By connecting these to a differential pressure switch or transmitter, you can calculate the actual air velocity or volume flow within the duct. These are the go-to choice for fan proving and ensuring that air is physically moving at the required speed, rather than just being pressurised.

The DFK Duct Fixing Kit includes 2m of 6mm i/d plastic tubing, 2 x pitot tubes and 4 fixing screws.

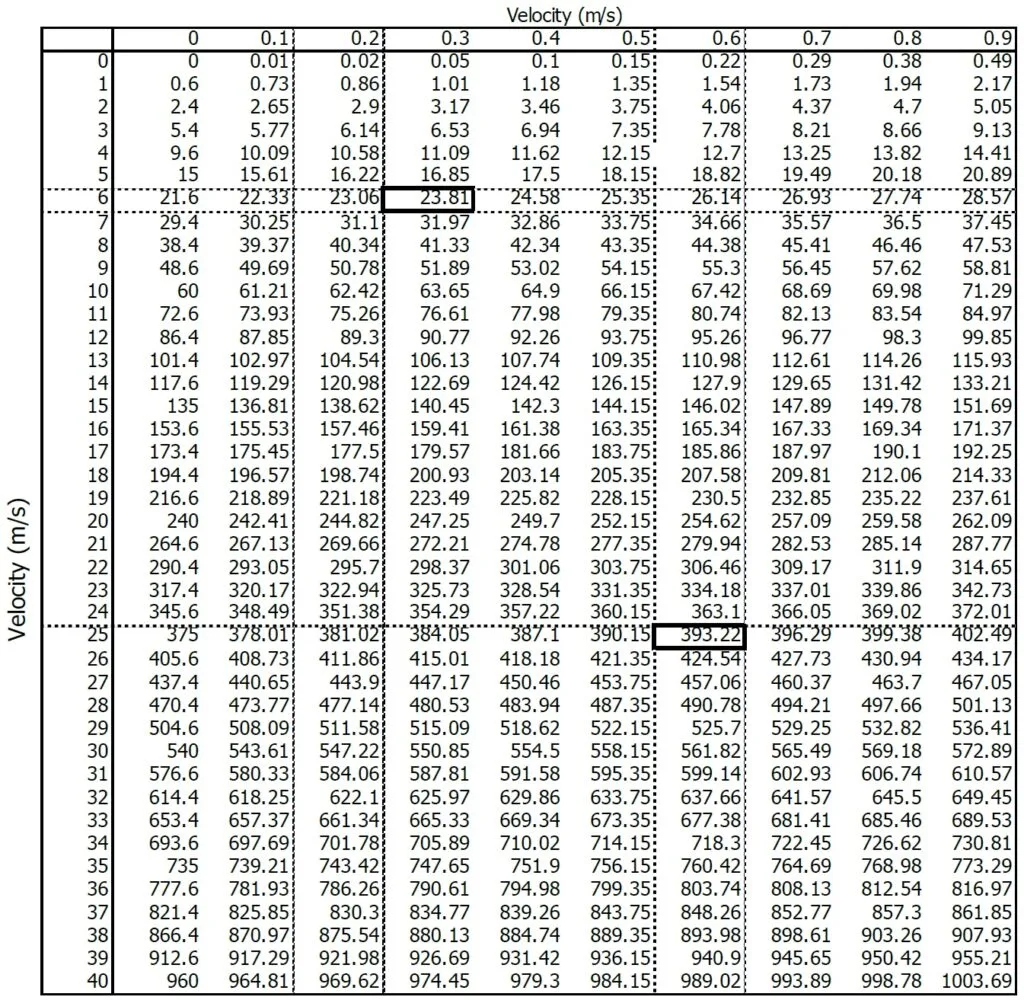

One Pitot tube should be in the direction of flow to get the higher dynamic pressure and the other against the direction of flow for the static pressure readings. The Differential pressures should be as shown on the table below.

Using the chart to determine the range of the differential pressure sensor:

From the left hand column (velocity, in 1 m/s increments) and the top row (velocity, in 0.1 m/s increments), read across and down to find the corresponding differential pressure.

Examples:

Air velocity is 6.3m/s – Read across from the left to 0.3m/s and down from the top to 6m/s. Where the column and row meet gives a differential pressure of 23.81Pa. Therefore, a differential pressure sensor, with a range of 0 – 25Pa should be selected.

Air velocity is 25.6m/s – Read across from the left to 0.6m/s and down from the top to 25m/s. Where the column and row meet gives a differential pressure of 393.22Pa. Therefore, a differential pressure sensor, with a range of 0 – 400Pa should be selected.

If you require a set of probes designed for monitoring clean rooms, or simple static pressures, the DP-AK set linked below would be more suitable.