Downloads

Safeye Quasar 900 Series

Description

The SafEye Quasar 900 Series is the very latest open path IR technology and detects a wide range of hydrocarbon gases – including alkanes (methane to hexane) and ethylene. Spectrex invented the xenon flash lamp design that revolutionized the open-path gas detection market, which, until then, was plagued by false alarms due to the drawbacks of the previous designs. Now, Open path detectors complement the use of individual point detectors, take executive action and offer many significant benefits.

Features

- Detects Hydrocarbon gases including methane, ethylene, Propane, Ethane, Butane etc.

- Detection range: 7-200m in three different models (same detector different sources)

- Built in event recorder – real time record of the last 100 events

- Fast connection to Hand-Held for prognostic and diagnostic maintenance

- Heated optics

- SIL2 approved, per IEC61508

- Outputs:

- 0-20mA

- HART protocol for maintenance and asset managements

- RS-485, Modbus Compatible

- High reliability – MTBF minimum 100,000 hours

- User programmable via HART or RS-485

- 3 years warranty

- Ex approval:

- FM/FMC approved per – Class I Div 1 Group B, C and D; Class I, II Div 1 Group E, F and G

- ATEX & IECEx approved per – Ex d e ib [ib Gb] IIB + H2 T4 Gb; Ex tb IIIC T135°C Db

- Performance test: Approved to FM6325 and tested per EN60079-29-4 by FM

Applications

- Offshore platforms & FPSOs

- Petrochemical plants

- Chemical processing plants

- Gas filling and distribution terminals

- Gas transport and pipelines

- Large storage areas & buildings

- Perimeter monitoring

The Quasars 900’s high power xenon lamp will compensate for changing weather conditions, including rain, fog, mist, snow and makes it immune to influences from solar radiation, arcwelding, stack flares or vibration from machinery. The optical lenses are thermostacically heated to prevent the formation of ice and build up of snow on the optics even under severe weather conditions. It also eliminates build up of condensation on the lenses. Quasar is rated for operation over a very wide temperature range from -67°F to + 149ºF (-55ºC to + 65ºC)

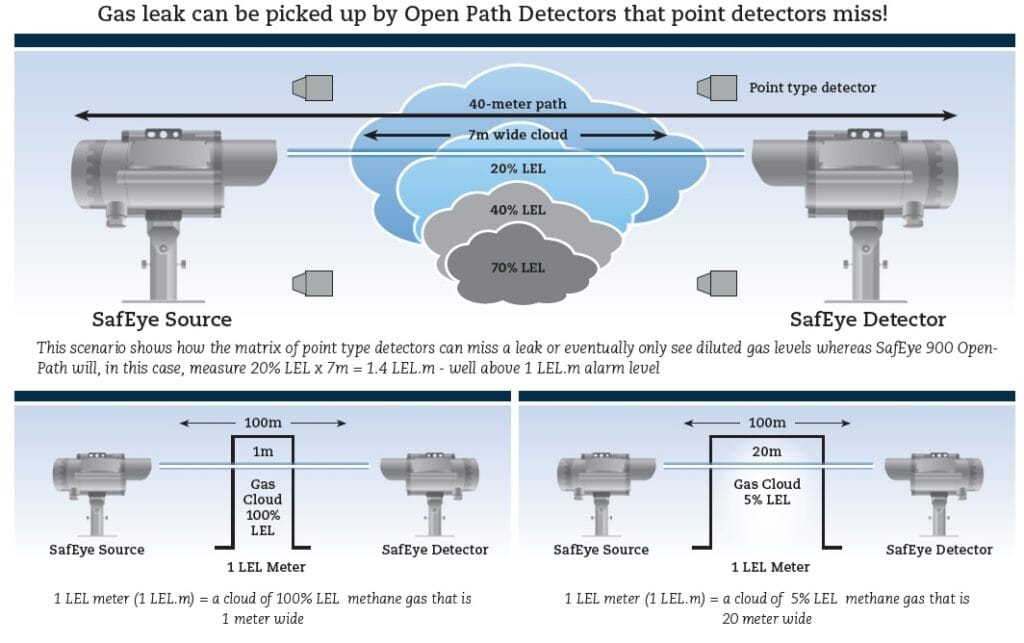

The SafEye detection system monitors the level of gas present between the transmitter and receiver units and provides a measurement out in LEL.meters instead of in %LEL as used with point type gas detectors. Both examples below show gas clouds with readings in LEL.meter.

Specifications

| Detection Range

|

Model | 901 | 902 | 903 | 904 |

| Feet | 23-66 | 50-132 | 115-330 | 265-660 | |

| Meters | 7-20 | 15-40 | 35-100 | 80-200 | |

| Detected Gas | C1-C8 | ||||

| Response Time | 3 Seconds | ||||

| Sensitivity Range | 0-5 LEL.m Methane and Propane | ||||

| 0-8 LEL..m Ethlene | |||||

| Minimum Detectable Level | 0.15LEL.m | ||||

| Power Supply | 24vDC Nominal (18-32vDC) @ 250mA (300mA Peak) | ||||

| 0-20mA Current Output | Gas Reading 4-20mA, Sink (Source Option). Faults below 4mA | ||||

| RS485 Interface | Modbus. Data to PC, Control Commands from PC or handheld unit | ||||

| HART | HART Communications on 0-20mA analogue current | ||||

| Visual Status Indicators | 3 Colour LED: Green – Power On; Yellow – Fault; Red – Alarm | ||||

| Hazardous Area Approval

|

ATEX/IECEx | Ex d e ib [ib Gb] IIB+H2 T4 Gb | |||

| Ex tb IIIC T135°C Db | |||||

| FM/FMC | Class I Div. 1 Groups B, C and D | ||||

| Class II/III Div.1 Groups E, F and G | |||||

| Inmetro | Ex d e ib [ib Gb] IIB+H2 T4 Gb | ||||

| Enclosure: | The Detector and Source all 316 Stainless Steel with electro polish finish. | ||||

| Weight | Detector | 5Kg | |||

| Source | 5Kg | ||||

| Operating Conditions | -55 to 65°C (-67 to 149F), 0-95% RH non-condensing | ||||