Downloads

OMNI-TDI-200H Ultrasonic Flow Meter

Description

The Omni-TDI-200H is a state-of-the-art, portable ultrasonic flow meter designed for highly accurate, non-invasive liquid flow measurement. Using the time-of-flight method, this device provides reliable data across a wide range of pipe sizes and materials, making it an indispensable tool for various industrial, commercial, and utility applications.

Product Overview

The Omni-TDI-200H offers a robust and user-friendly solution for flow measurement without the need to cut pipes or disrupt operations. Its non-invasive design eliminates pressure drops, reduces maintenance, and ensures no contamination of the measured fluid. This makes it ideal for temporary measurement campaigns, but also an option for permanent installations where ease of setup and precision are paramount.

Features

- Non-Invasive Measurement

- High Accuracy

- Wide Measurement Range from 0.03 to 105 ft/s (±0.01 to ±32m/s)

- Supports pipes from 0.5″ to 240″ (DN15 to DN6,000mm)

- All common pipe materials, including metals, most plastics, and fiberglass.

- Integral Data Logger

- Displays instantaneous, accumulated flow rates, velocity in both Imperial or Metric units.

- Provides up to 10 hours of continuous operation on a full charge.

- IP54 Enclosure for durability in various environments.

- Features self-adjusting capabilities for optimal signal reception.

Working Principle: Time-of-Flight (Transit-Time) Flow Measurement

The Omni TDI 200H operates on the highly reliable time-of-flight principle, also known as transit-time ultrasonic flow measurement. This method involves:

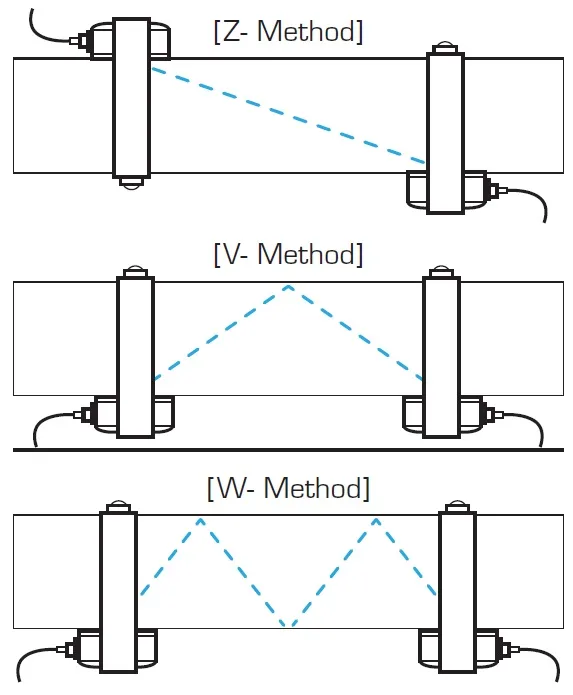

- Ultrasonic Pulse Transmission: Two ultrasonic transducers are clamped onto the exterior of the pipe. These transducers alternately transmit and receive ultrasonic pulses through the flowing liquid.

- Upstream and Downstream Measurement: When the fluid is flowing, the ultrasonic pulse travelling downstream (with the flow) is accelerated by the fluid’s velocity, arriving at the receiver faster. Conversely, the pulse traveling upstream (against the flow) is slowed down, taking longer to reach the receiver.

- Precise Time Difference Calculation: The flow meter precisely measures the minute time difference between these upstream and downstream transit times. This time difference is directly proportional to the average velocity of the fluid.

- Flow Rate Derivation: Based on the calculated fluid velocity and the known cross-sectional area of the pipe, the Omni TDI 200H accurately computes the volumetric flow rate.

This non-invasive approach offers significant benefits, including ease of installation without disrupting the pipeline, no moving parts to wear out, and no pressure drop across the measurement point. It is particularly effective for homogeneous, clean liquids with low concentrations of suspended solids or gas bubbles (typically less than 1% by volume, with particle sizes smaller than 75µm).

Standard Kit Components

The standard Omni-TDI-200H-Kit is equipped with transducers specifically designed for liquid temperatures ranging from 0 to +90°C, ensuring versatility for common applications. A typical standard kit includes:

- Omni-TDI-200H Main Unit: The portable flow meter device.

- Type S Transducers (TDI-S1): For small pipes (0.5″–4″ / DN15-DN100mm).

- Type M Transducers (TDI-M1): For medium pipes (2″–28″ / DN50-DN700mm).

- Type L Transducers (TDI-L1): For large pipes (11″–240″ / DN300-DN6,000mm).

- Transducer Mountings: Secure straps for various pipe sizes.

- Acoustic Coupling Gel: Essential for ensuring optimal ultrasonic signal transmission.

- Tape Measure: For accurate transducer spacing.

- Mains Charger: For recharging the internal battery.

- Operating Manual: Comprehensive guide for setup and operation.

- Protective Carry Case: For safe transport and storage of the complete kit.