Downloads

AV-MPS Air Velocity Probes

Description

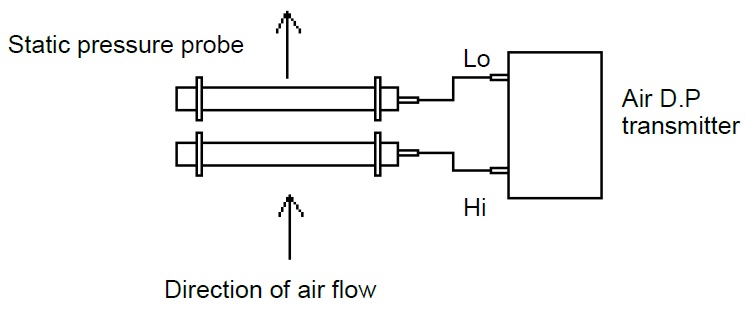

AV-MPS-1500 Multi-point Air Velocity Probes are 26mm in diameter and 1500mm long. Suitable for being mounted across a duct with 1,400mm to 1,600mm. They are used to ensure that recommended flow rates for public buildings and industrial plant are achieved. Using a PA-60-x, PA-65-x, PA-267-x or PA-699-x Air Differential Pressure Sensor of an appropriate range allow the flow rate to be monitored in real-time.

Features

- Push-on connectors to suit 6mm i/d PVC tubing

- Neoprene rubber gaskets duct seals included

- Probes can be adjusted ±100mm by adjusting gasket and flanges

- Averages across the duct

- Easy installation

- Fully compatible with PA-267, PA-60-x, PA-65-x or PA-699 DP pressure transmitters

Installation

- One probe should be fixed with the holes pointing directly into the airflow, the other probe can be rotated to achieve the correct reading(via a D.P. sensor) when compared to a reference probe used for commissioning.

- All the above is to try to ensure that the probes are sited in laminar airflow rather than turbulent airflow, to achieve maximum accuracy and repeatability.

- If the probes are to be installed in a round duct mount them side-by-side approx. 100mm apart. If the probes are to be mounted near a bend or branch in the duct mount them above each other approx. 100mm apart. Using a flange as a template, mark the duct work and drill the mounting holes.

- Turn the total pressure probe so that the holes face directly into the air flow. Lock in position using the pan-head screws on the flanges.

- If possible, adjust the speed of the fan to give a known air velocity. Turn the static pressure probe so that a differential pressure corresponding to the known air velocity is measured across the 2 probes. Lock in position using the pan-head screws on the flanges.

- Where fan speed adjustment is not possible, measure the air velocity with a vane anemometer (or similar). Turn the static pressure probe so that a differential pressure corresponding to the measured air velocity is measured across the 2 probes. lock in position using the pan-head grub screw.

Assembly of AV-MPS

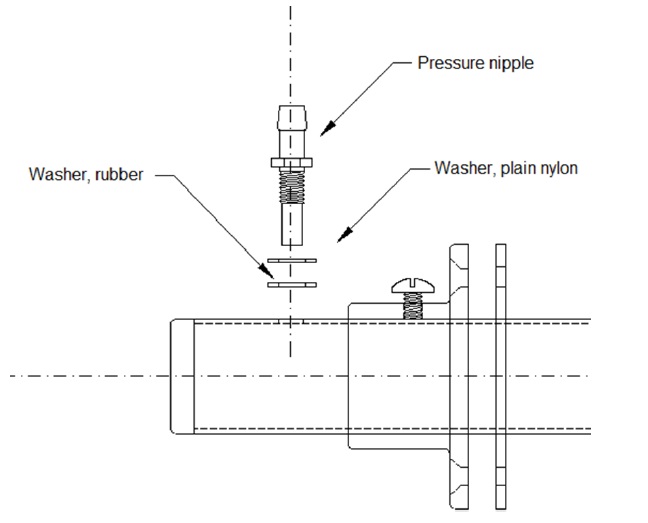

- Locate the M6 thread cut into one end of the probe.

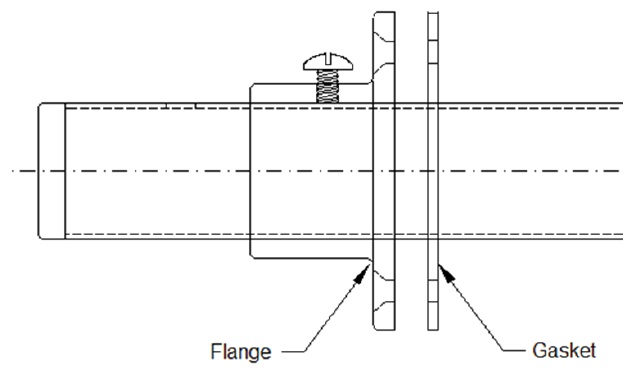

- Slide gasket first followed by the flange down the tube approximately 100mm and tighten the grub screw.

- Place the nylon washer then the rubber washer onto the pressure nipple , and hand tighten into the M6 thread hole in the probe.

- Cut 32mm diameter holes at opposite sides of the duct.

- Pass though the end without the gasket/flange into the duct until this is out the other side.

- Fit the remaining gasket followed by the flange.

- Making sure that there is good compression on both side of the ducts allowing the gaskets to make an air tight seal, secure the flanges in place using the supplied screws then tighten the grub screws.