What is a data logger?

A data logger is a device that can measure a variety of signals and store the data internally for later retrieval. Compared to older style chart recorder systems, data loggers have many benefits including the ability to log multiple signals, compact dimensions and low overall running costs. Data acquisition systems should not be confused with data logger systems. Acquisition systems rely on a dedicated computer to sample the readings, whilst a typical data logger will store it's readings to its internal memory without the need for a PC.

What types of data logger are there?

As a general rule of thumb, data loggers fall into in two main types…

Single channel data logger: This generally is a small, compact unit that will have one input to measure a fixed signal, such as a temperature reading. Memory is usually quite small, between 16,000 and 80,000 readings and the logging rate - which is how quickly it can store the values, is usually programmable between once a second to once a day.

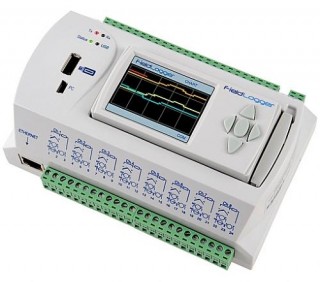

Multi-channel data logger: These are usually larger than the single channel units, but still smaller than a mechanical chart recorder, and have multiple channels to measure a variety of sensors. Memory is typically 100,000 or more readings, and some devices have the ability to accept external memory cards which enable millions, or billions, of data points to be stored. Logging rates to can also be increased due to the larger memory, with some units having the ability to store readings hundreds or thousands of times a second.

What are data logger sample and recording / logging rates?

The sample rate is the rate at which the data logger can measure the value of an input channel, whereas the logging rate relates to how often that value is stored to memory. For example, if you require to monitor the lowest temperature in a freezer over a month, the sample rate could be set at once a second. In a small single channel data logger, that would fill up its memory very quickly, so the logger could be set to sample the temperature value every second, but only store the lowest value over a five minute period at the end of each period. This saves internal memory, allowing the unit to run for longer and also cuts the amount of logged data you need to work with.

What are universal and fixed inputs?

A fixed input is a channel on a data logger which is designed to measure one type of signal. This might be a dedicated K-Type thermocouple input, or a 4-20mA signal. A universal input allows a variety of sensors to be connected to one channel. Units such as the DataTaker can accept RTD’s, voltage, current or resistance signals on each channel.

What are single ended and differential inputs?

Multi-channel data loggers, such as the Squirrel range, have the option for single ended or differential wiring. In a single ended configuration, each input shares the ground or earth, while in a differential configuration each input has its own earth/common. For example, in the case of the Grant Squirrel data logger, a single ended wiring configuration can double the channels, from 4 to 8, or 8 to 16 and so on.

Why do we need differential inputs?

As above, we assume the common, or the earth, to be 0V. However, if you have a variety of sensors all powered by different power supplies, you can have a situation when the ground is not 0V, causing a difference between the other inputs. This leads to a ground, or earth loop, and can create large errors in your readings. Single ended configurations can also lead to noise errors. This is when the signal cable is able to pick up electrical activity, which again effects readings. Differential inputs are made of two inputs, one monitoring 0V and the other monitoring the signal. These two values are then monitored by a third circuit which measures the difference between the two readings, thus giving you a true measured value.

Resolution

Data loggers use an ADC (analogue to digital converter) to convert incoming analogue signals to digital format. All ADC’s have a resolution, which can range from 8 to 24 bit. Low cost and older data loggers typically have a resolution of 8 bits. This means that the recorded value of the analogue measurement would be 256 steps over the full range of the signal. For example, if a 0-10V DC signal input is connected to an 8 bit input channel you can calculate the resolution of the recorded measurement as follows:

10V DC / 256 (8 bits) = 0.04V DC

The above signal has to change by 0.04V to see a change, this sounds like a lot but if you have a 10,000 PSI pressure transmitter, this would be a +/- 40 PSI change in value.

More expensive data loggers have a better ADC, 16 bit or 65,536 steps, using the above example…

10V DC/ 65,536 (16 bits) = 0.00015V DC

Again, using this for our 10,000 PSI pressure transmitter, you could see a change of just +/- 0.15 PSI.

Part two of this guide to follow....